The world of digital fabrication has witnessed a revolution in recent years, thanks to advancements in versatile tools like a 3D printer, laser engraver, and CNC cutter. While each of these devices is powerful in its own right, combining them unlocks an entirely new realm of possibilities for makers, designers, and engineers. If you’re using the best 3D printer, partnering it with a laser engraver and CNC cutter can transform your creative projects into professional-grade results. Here’s a closer look at how these tools complement each other, their unique applications, and tips for leveraging them together effectively.

Understanding the Three Tools: A Synergistic Partnership

1. 3D Printer

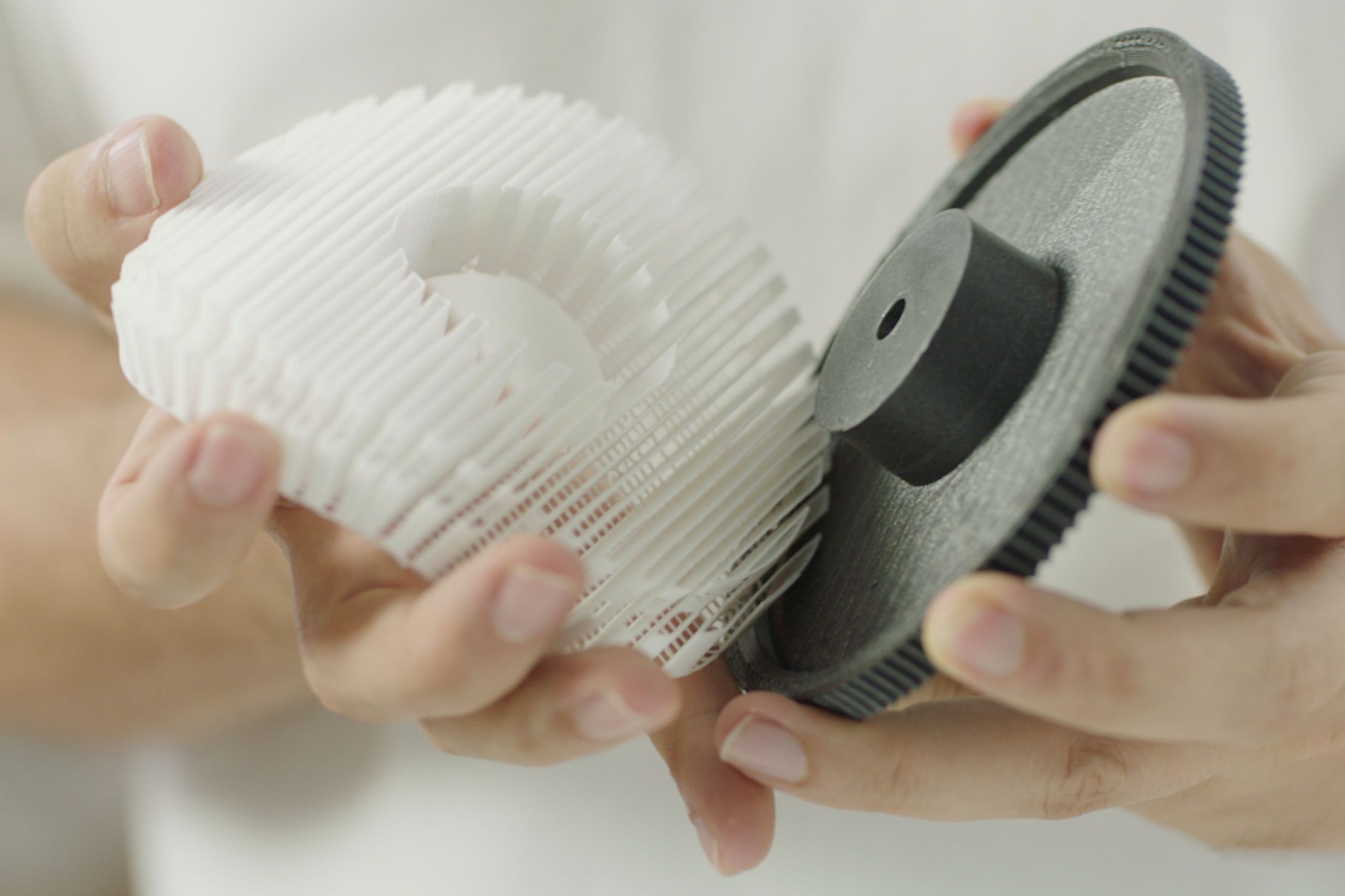

A 3D printer builds objects layer by layer using materials like PLA, ABS, or resin. Its primary function is to transform digital designs into physical prototypes or products.

- Applications: Prototyping, custom tools, miniatures, and functional parts.

- Strength: Offers high precision and intricate designs with minimal material waste.

2. Laser Engraver

A laser engraver uses concentrated light to cut or etch materials. Unlike a 3D printer, which builds up layers, a laser engraver works subtractively, removing material for desired patterns.

- Applications: Etching designs on wood, metal, or acrylic, cutting intricate shapes.

- Strength: Excels in fine detailing and rapid material processing.

3. CNC Cutter

A CNC cutter uses a rotating cutting tool to carve or mill materials. It’s often used to create high-strength components from wood, metal, or plastic.

- Applications: Furniture making, metal parts, molds.

- Strength: Provides superior strength and durability for functional products.

Benefits of Combining 3D Printing, Laser Engraving, and CNC Cutting

Integrating these tools allows makers to:

- Create Multi-Material Projects: Combine plastic 3D-printed parts with engraved wooden bases or CNC-milled metal components.

- Enhance Aesthetic Appeal: Use a laser engraver to add intricate designs or textures to 3D-printed items.

- Increase Functionality: CNC cutters and 3D printers together enable the creation of robust mechanical components with personalized details.

- Optimize Time and Costs: Streamline workflows by using the best tool for each task in a project, minimizing manual work.

For example, with the best 3D printer, you could prototype a design, refine its appearance with laser engraving, and produce structural parts using CNC machining.

Real-World Applications

1. Custom Product Design

Combine 3D printing for intricate forms, laser engraving for branding or decorative patterns, and CNC cutting for robust product bases or molds.

Example: Design a custom smartphone stand. Use 3D printing for the stand’s structure, a laser engraver to etch a logo or pattern, and a CNC cutter to craft a durable wooden base.

2. Jewelry Making

Create stunning, mixed-material jewelry by printing complex forms with a 3D printer, engraving designs on metal with a laser, and using a CNC cutter to carve gemstone settings.

Example: A resin-printed necklace paired with engraved gold plating and CNC-milled accents.

3. Robotics and Engineering

Leverage all three tools to design intricate robotic components.

Example: Print plastic gears and housings with a 3D printer, engrave serial numbers with a laser, and CNC-machine aluminum chassis parts for strength.

Best Practices for Using the Tools Together

- Plan Your Workflow Determine which tool is best for each part of your project. Start with 3D printing for prototypes or non-load-bearing parts, laser engravers for aesthetics, and CNC cutters for structural strength.

- Optimize File Compatibility Ensure your design files are compatible across different machines. Many software platforms support multiple fabrication methods, but careful preparation is key.

- Choose the Right Materials Each tool has material compatibility constraints. For example:

- Use PLA or ABS for 3D printing.

- Choose wood or acrylic for laser engraving.

- Opt for aluminum or hardwood for CNC cutting.

- Invest in Modular Machines Some advanced machines combine 3D printing, laser engraving, and CNC cutting in a single device, saving space and streamlining operations.

Challenges and How to Overcome Them

- Material Handling: Switching between tools may require material adjustments (e.g., post-processing printed parts before engraving). Solution: Plan for transitions and ensure materials are prepared for each step.

- File Preparation: Each tool may require unique file settings, such as STL files for 3D printing and DXF files for laser engraving or CNC cutting. Solution: Use versatile software that supports multi-format outputs.

- Tool Compatibility: Ensure that the tools can work seamlessly in a workflow. Solution: Research compatibility between your devices or consider all-in-one machines.

Future Possibilities

The combination of 3D printing, laser engraving, and CNC cutting is only the beginning. Emerging technologies such as AI-driven design software and hybrid manufacturing systems are expanding what makers can achieve. With the best 3D printer, makers can expect even more precision, speed, and versatility in projects.

Final Thoughts

Pairing a 3D printer with a laser engraver and CNC cutter is a game-changing approach for makers who want to create projects that are both functional and visually striking. By understanding the strengths of each tool and how they complement one another, you can take your designs to the next level. Whether you’re crafting jewelry, building robotics, or prototyping new products, the possibilities are endless with the best 3D printer as part of your toolkit.